Buying the right way is just as important as buying the right thing.

Procurement is that critical step - it's not just about making a purchase, but about choosing a path that leads to the best value and partnership for your company. With the right procurement method, you can turn simple buying into a strategic asset.

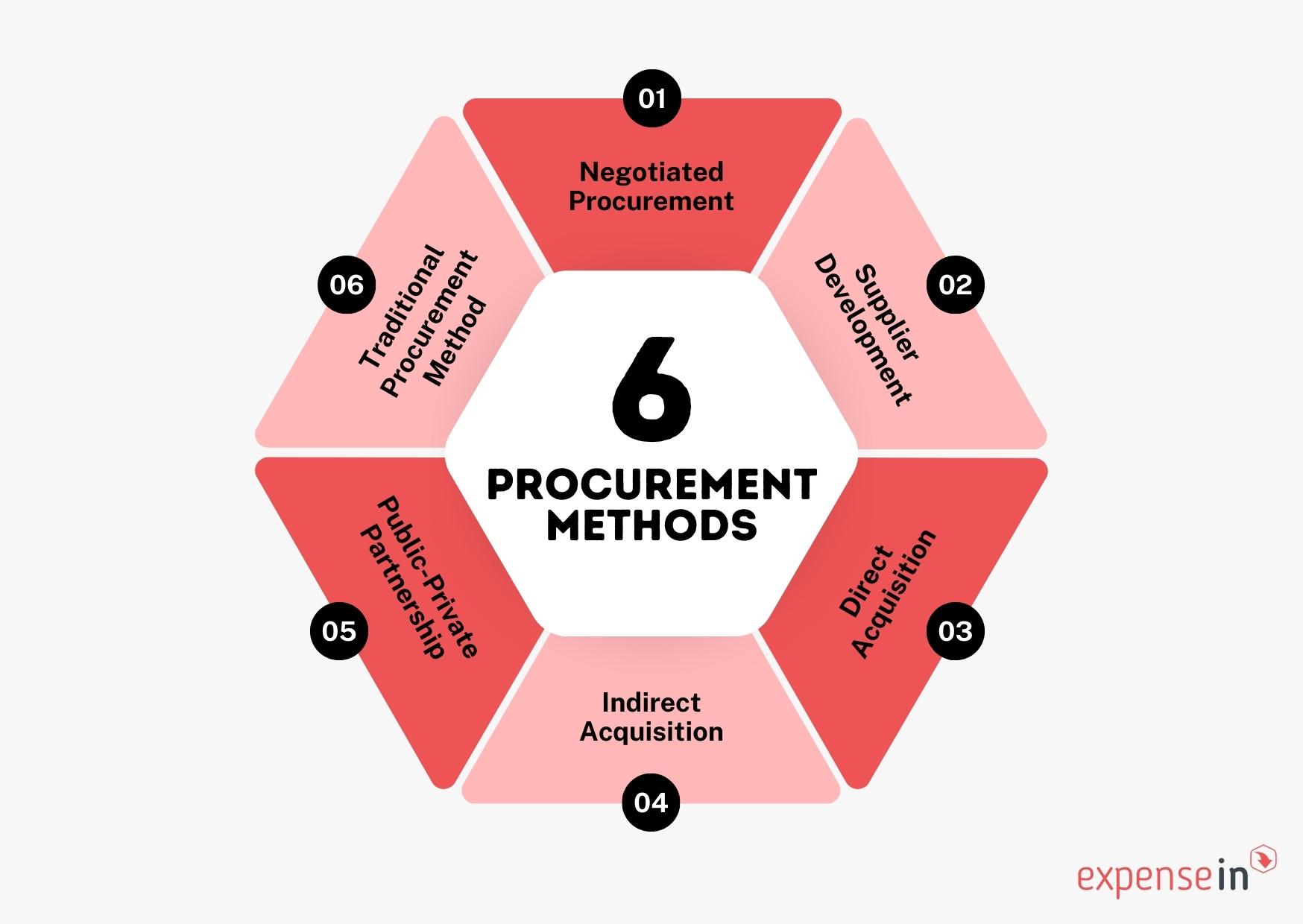

But with six different procurement methods to choose from, how do you know which path is the right one?

It's a decision that can feel overwhelming, but it doesn't have to be. This guide is your map through the procurement maze, offering clear insights into each method to help you make choices that are not just good, but great for your business.

What is Procurement?

At its heart, procurement is the strategic process businesses use to find and obtain the goods and services they need.

It's not just about buying; it's about making smart choices. When businesses talk about procurement, they're looking at the bigger picture: ensuring they get quality products, at the right price, from reliable suppliers, and at the right time.

In today's competitive market, the right procurement methods can make a significant difference. It's about leveraging buying power, building strong relationships with suppliers, and ensuring a steady and reliable supply chain.

Procurement vs. Purchasing: What's the Difference?

While they might seem similar, there's a distinct difference between procurement and purchasing:

While they might seem similar, there's a distinct difference between procurement and purchasing:

Purchasing: This is the act of buying. It's straightforward - you need something, you buy it. It's a transaction, often based on immediate needs.

Procurement: This is the whole process. It starts with identifying what's needed, then researching suppliers, negotiating terms, and finally making the purchase. But it doesn't stop there. Procurement also involves evaluating the effectiveness of the purchase and the relationship with the supplier.

In a nutshell, purchasing is a single step, while procurement is the entire journey. And as businesses aim to grow and thrive, understanding this journey and the various procurement methods available becomes crucial.

The Six Main Procurement Methods

Ever wondered how businesses decide where to get their supplies from? It's not as simple as popping into a store or clicking 'buy now' online. There are strategies and methods behind these decisions.

Ever wondered how businesses decide where to get their supplies from? It's not as simple as popping into a store or clicking 'buy now' online. There are strategies and methods behind these decisions.

Let's dive into the six main ways businesses go about this:

1. Negotiated Procurement

Negotiated procurement is like a dance between businesses and suppliers.

Instead of just picking an item from a set price list, both parties sit down and hash out the terms. It's about crafting a deal that's mutually beneficial. From prices to delivery timelines, everything is up for discussion.

Pros & Cons of Negotiated Procurement

Pros:

Pros:

Customised solutions: Tailored agreements ensure that specific needs are met, leading to potentially better outcomes.

Relationship building: Direct negotiations foster stronger, long-term relationships with suppliers, paving the way for future collaborations.

Flexibility: The ability to negotiate terms allows for adaptability to changing circumstances or requirements.

Cons:

Potential for subjectivity: Without a structured bidding process, there's a risk of decisions being influenced by biases.

Resource intensive: Negotiations can be lengthy, requiring significant time and effort from both parties.

Higher complexity: Negotiated procurement often involves complex deal structuring, which can complicate the procurement process and require specialised knowledge or legal assistance.

When is Negotiated Procurement the Best Choice?

Specialised projects: If you're working on a project that doesn't fit the mould, negotiated procurement can help you source materials or services that are just right.

Limited suppliers: In industries where suppliers are few or have niche expertise, direct negotiations ensure you get the best value and terms.

Complex requirements: For projects that have multiple layers or intricate details, this method allows for a deep dive into specifics, ensuring both parties are on the same page.

2. Supplier Development

Supplier development is all about collaboration.

Businesses don't just buy from suppliers; they actively engage with them, offering resources, training, or even technology to help them improve. It's a partnership where both parties work hand-in-hand, aiming for mutual business growth and success.

Pros & Cons of Supplier Development

Pros:

Pros:

Enhanced supplier performance: Investing in suppliers can lead to improvements in quality, reliability, and delivery times.

Strategic alignment: Close collaboration ensures that suppliers align with the company's strategic goals and values.

Risk mitigation: By understanding and supporting suppliers, businesses can anticipate and mitigate potential supply chain risks.

Cons:

High initial investment: Significant resources may be needed upfront to develop suppliers.

Over-dependence: Relying too heavily on a few developed suppliers can pose risks if those suppliers face challenges.

Long-term commitment required: Supplier development is a long-term strategy that may not yield immediate results, requiring sustained commitment and patience from the business.

When is Supplier Development the Best Choice?

Building strong bonds: If you're looking to go beyond mere transactions and build lasting trust and understanding, supplier development is the way to go.

Ensuring a smooth supply chain: For businesses that rely heavily on a consistent and reliable supply chain, nurturing and investing in suppliers can be a strategic move.

Facing rapid market changes: In industries where the market landscape is rapidly evolving, helping suppliers adapt and grow ensures that your supply chain remains resilient and agile.

3. Direct Acquisition

Direct acquisition is all about simplicity and clarity.

Businesses identify what they need and go directly to the producer or service provider to make the purchase. There's no third-party involvement, which means no additional mark-ups or potential communication barriers.

Pros & Cons of Direct Acquisition

Pros:

Pros:

Cost savings: Eliminating intermediaries can lead to direct cost savings.

Streamlined communication: Direct interactions can reduce misunderstandings and ensure clarity in requirements.

Quicker turnaround: Without the need for intermediary processes, procurement can be faster.

Cons:

Limited market knowledge: Without intermediaries, businesses might miss out on broader market insights or better deals.

Increased responsibility: The onus of vetting and managing suppliers falls entirely on the business.

Narrower supplier base: Direct acquisition often limits the business to a smaller pool of suppliers, which can reduce competitive pricing and innovation.

When is Direct Acquisition the Best Choice?

Routine buys: For regular, recurring purchases where the requirements are well-known, direct acquisition is a no-brainer.

Clear specifications: When you know exactly what you want, down to the tiniest detail, it's best to go straight to the source to ensure your needs are met.

Trusted suppliers: If you've built a strong relationship with a supplier and trust their quality and reliability, direct acquisition streamlines the process.

4. Indirect Acquisition

Indirect acquisition is like having a seasoned guide in the complex world of sourcing.

Businesses collaborate with third parties or intermediaries, such as agents, brokers, or consultants, who have the expertise and connections to find the best suppliers.

These intermediaries navigate the market, negotiate terms, and often handle logistics, making the acquisition process smoother.

Pros & Cons of Indirect Acquisition

Pros:

Pros:

Access to expertise: Intermediaries bring specialised knowledge and insights, potentially leading to better deals.

Risk distribution: Using intermediaries can spread the risks associated with procurement.

Time savings: Intermediaries can handle various procurement processes, saving businesses time.

Cons:

Additional costs: Intermediaries will have their fees or mark-ups, potentially increasing costs.

Potential misalignment: Intermediaries might not always fully align with the business's specific needs or values.

Loss of control: Relying on intermediaries may result in less direct oversight of the procurement process, potentially leading to outcomes that don't fully meet the business's expectations.

When is Indirect Acquisition the Best Choice?

Limited in-house expertise: If your business lacks the expertise or resources to source directly, an intermediary can fill that gap.

Diversifying suppliers: When looking to expand or diversify the supplier base, intermediaries can introduce businesses to new, vetted suppliers.

Complex markets: In industries or markets that are intricate or rapidly changing, having an expert intermediary can be invaluable.

5. Public-Private Partnership

A public-private partnership (PPP) is a collaborative effort between government entities and private-sector companies.

The goal? To jointly deliver public services or undertake significant projects.

By pooling resources and expertise, PPPs aim to achieve outcomes that might be challenging for either sector to accomplish independently.

Pros & Cons of Public-Private Partnership (PPP)

Pros:

Pros:

Resource pooling: Combining resources can lead to more significant projects and better infrastructure.

Risk sharing: Both public and private entities share the risks, leading to potentially more sustainable projects.

Innovation boost: The private sector can introduce innovative solutions to public projects.

Cons:

Complex governance: Managing a PPP requires navigating both public and private sector governance structures.

Longer negotiation periods: Establishing a PPP can be time-consuming due to the complexities involved.

Accountability issues: The blending of public and private sector roles can sometimes lead to confusion about who is accountable for various aspects of the project, potentially complicating project management and outcomes.

When is PPP the Best Choice?

Large-scale projects: Infrastructure developments like roads, airports, or utilities often require vast resources and expertise, making them ideal candidates for PPPs.

Specialised services: When a public service requires specialised knowledge or technology, partnering with a private entity can bring in the necessary expertise.

Resource allocation: In situations where public funds are limited, partnering with the private sector can help bridge the resource gap, ensuring project completion.

6. Traditional Procurement Method

The traditional procurement method is like the classic recipe that's been passed down through generations - it's reliable, straightforward, and has stood the test of time.

At its core, this method is about setting clear expectations, letting suppliers compete, and choosing the best fit based on value or price.

Pros & Cons of Traditional Procurement Method

Pros:

Pros:

Transparency: A structured bidding process ensures fairness and transparency.

Market-driven pricing: Competitive bidding can drive down prices, ensuring value for money.

Clear criteria: With set specifications, there's clarity in expectations and deliverables.

Cons:

Potential limitations: A rigid bidding process might limit innovative solutions or approaches.

Administrative burden: Managing bids and evaluating them can be resource-intensive.

Inflexibility in contracts: Once a contract is awarded, there may be limited scope for adapting to changes or unexpected challenges without renegotiation, which can be cumbersome and time-consuming.

When is the Traditional Procurement Method the Best Choice?

Public sector projects: Given the need for transparency and accountability in public spending, this method is a favourite for government contracts.

Large-scale endeavours: For big projects where specifications are clear and the stakes are high, the traditional method offers a structured approach.

Standardised purchases: When buying standardised goods or services, where quality and specifications are well-known, this method ensures competitive pricing.

How to Choose the Right Procurement Method

With various options available, each offering unique benefits, the challenge lies in selecting the one that aligns best with your needs.

Let's explore the factors that should guide this decision:

Key Factors to Consider When Choosing a Procurement Method

Nature of your project: Different projects have different demands. For large-scale endeavours with clear specifications, the traditional procurement method might be ideal. However, specialised projects might benefit from the flexibility of negotiated procurement.

Budgetary constraints: Your financial boundaries can guide your choice. If you're looking for competitive pricing, the traditional procurement method, with its emphasis on open bidding, might be the way to go.

Supplier relationships: The history and strength of your relationships with suppliers can influence your method choice. A strong, pre-existing bond might make negotiated procurement or supplier development more appealing.

Market dynamics: A deep understanding of the current market, including pricing trends and supplier availability, is crucial. If you lack in-house expertise, indirect acquisition can offer broader insights.

Risk tolerance: Every procurement method comes with its set of risks. Assessing your company's risk appetite can help in choosing a method that aligns with your comfort level.

Transparency needs: If transparency is a top priority, especially for public sector entities, methods like traditional procurement, which prioritise open processes, might be more suitable.

The Influence of Business Size, Industry, & Specific Needs

Business size: Large corporations with extensive resources might find negotiated procurements or supplier development more feasible. In contrast, smaller businesses might gravitate towards the simplicity of direct acquisitions.

Industry trends: Your industry can dictate preferences. For instance, the construction sector might lean towards traditional procurement for its transparency, while tech industries might value the adaptability of negotiated procurement.

Specific needs: Tailoring your choice based on specific business requirements is crucial. If innovation is a priority, supplier development might be the best fit. For standardised needs, direct or indirect methods could be more appropriate.

Remember, no procurement method is set in stone. As your business grows and industry dynamics shift, your procurement needs will evolve. It's essential to conduct periodic reviews of your procurement strategy, gathering feedback from both internal teams and suppliers.

This continuous feedback loop will not only optimise your current processes but also ensure you're well-prepared for future challenges and opportunities.

The Role of Technology in Modern Procurement Methods

The integration of technology into business operations has significantly impacted procurement methods.

As companies seek to optimise their procurement processes, technology offers solutions that enhance efficiency, transparency, and decision-making.

Digital sourcing & e-procurement: Modern procurement methods have shifted towards digital platforms, allowing businesses to source suppliers, evaluate bids, and finalise contracts online. E-procurement platforms streamline these processes, reducing time and increasing accuracy.

Enhanced supplier management: Technology provides tools for better supplier relationship management. Businesses can now monitor supplier performance, ensure compliance, and evaluate contract terms using digital systems, ensuring that suppliers align with company standards and expectations.

Automation in procurement: One of the significant advantages of technology in procurement is finance automation. From generating purchase orders to tracking deliveries, automated systems reduce manual tasks, minimise errors, and improve efficiency.

Data-driven decisions with predictive analytics: Predictive analytics in procurement allows businesses to forecast market trends, anticipate supply chain disruptions, and make informed purchasing decisions. This data-driven approach ensures that companies can optimise their procurement strategies based on real-time insights.

Conclusion: Elevate Your Strategy with the Right Procurement Methods

Choosing the right procurement method isn't just smart business - it's essential. It can mean the difference between just getting by and truly excelling in your industry.

As we've seen, each method has its place and purpose. The key is to match your business needs with the right financial strategy.

Embrace the change that technology brings to procurement. It's not just a trend; it's the new standard. The right tools can streamline your processes, save money, and give you insights that keep you steps ahead of the competition.

So, take a moment to reflect on your procurement strategy. Are you using the best method for your needs? Are you leveraging technology to its fullest?

The choices you make today will define your business' success tomorrow. Choose wisely, and watch your business grow.